The effects that built-up areas, power, and the way you hang your luminaires have on the illuminance of your space

Everything has an effect on everything around it. When designing lighting, it is useful to consider how built-up the hall is, the height of its ceilings, and the power of the luminaires. An unsuitable combination of parameters can cause unexpected problems and thwart your investments.

Every machine casts a shadow. The areas of the hall that are built-up with machines will cause shadowing – period. Shadows cannot be prevented, but they can be suppressed by the proper placement of your luminaires. This depends on the height at which they are hung. The lower the lights, the denser the grid should be to provide uniform illuminance. An additional factor is the power of the luminaires. The lower the hanging height and the denser the built-up section of the space is, the lower the power and the denser the grid of the luminaires is necessary.

More light!

… said old Goethe on his deathbed, and we know why. Let’s look at an example below.

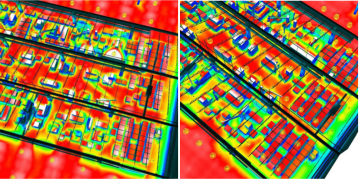

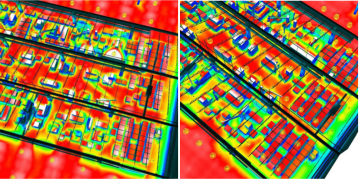

In the image on the left, you can see a part of the factory hall with an average illuminance of 500 lx, which is provided by luminaires with an input of 160 W placed in a thin grid at a height of 6 meters. The hall is very densely built-up with machines and other objects. The risk of shadows is large, and the lighting is quite uneven. If you wanted to reconstruct your lighting system and test out your plan “in an empty hall”, none of these risks would appear until actual operation began, which, let’s be honest, is the definition of “too late”.

In the image on the right, you can see the same section of the hall in a new light: 80 W luminaires have been hung at the same height but in a denser grid. When measuring the illuminance for an empty hall everything is fine, but this time in actual operating conditions the illuminance is much better; the illumination in the aisles between machines is acceptable. At first glance the difference is not highly visible; have a look, however, at the details:

The unsuitable design is on the right and the successful one on the left. In the image on the left, the decrease in illluminance due to the selected lighting and shadowing from 500 lx to 80 lx is unacceptable. In the correct design, the decrease is acceptable. The critical points can then easily be illuminated by a local auxiliary light source.

Give yourself some leeway

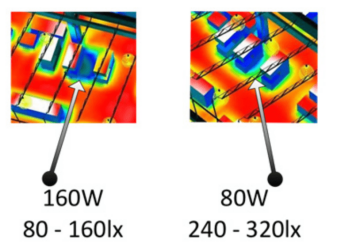

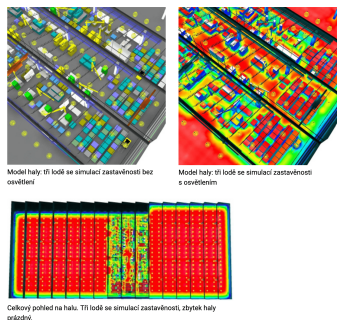

Contractors often ask whether or not and how they should increase the power of lighting systems to be prepared for shadows and fluctuations in illumination. Using an example situation, we presented the client with a proposal of a hall comprised of several bodies. In three of them, we modeled in machines according to actual conditions while leaving the others empty.

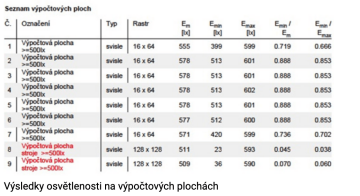

Results of illuminance on calculated surfaces

As you can see, with the same grid and luminaire power, the illuminance in bodies with machines is as much as 65 lx lower than in bodies where the built-up areas were ignored. In order to ensure high-quality lighting, it would be necessary to increase the required illuminance from the originally calculated 500 lx to 575 lx in order for the built-up hall to reach an average of 500 lx.

It should also be mentioned that increasing performance also increases the purchasing price and the operational costs of installation. This is of course an acceptable price to pay when considering that the quality and safety of the whole production process rely on the quality of illumination.