Our lighting didn't even sweat in the foundry

We began producing the TaMAX line of luminaires based on our long-standing experience and a clear goal in mind – to create a product that could withstand even the toughest conditions. Although we were familiar with the conditions in heavy industry and had access to adequate technologies, the path to creating this extreme luminaire was still a challenging one.

Developing a high-quality industrial luminaire is a rather labor-intensive, expensive, and complex task. You have to find, recognize, and select high-quality (and truly industrial) electronic components. It is equally important to design a proper body for the luminaire. Last but not least, you have to know how to produce and test these luminaires to perfection.

Leave the heat on the manufacturer – your luminaires need to stay cool

Removing heat from the luminaires is the alpha and omega of the economics of industrial luminaires. The overheating of components shortens the lifespan of the whole system and makes the return (or even sense) of your investment more problematic. It’s not a surprise that we paid so much attention to heat with our TaMAX line luminaires, and it paid off in the end.

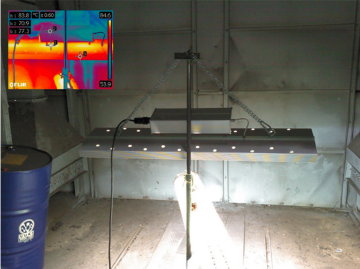

The difference between the heat on the LED chips and the surrounding environment does not exceed 20°C. A temperature of 85°C is considered to be beyond the chip’s functional comfort zone. So, the temperature can be as high as 65°C and the chip will still keep its cool.

We placed the driver far away from the hot LED chips. In the Doublepower TaMAX SKY product, the driver is actually isolated in a separate box that functions as a cooling body for the driver. Thus, the heat difference between the driver box and the area surrounding the luminaire does not exceed 16°C. In Doublepower’s TaMAX TREE product, the driver is placed in a shared component, but like the SKY product, it is placed away from the chips and at a larger distance from them than the Doublepower TREE basic version. Therefore, the heat from the chips to the driver is kept to a minimum.

A love for tape

It was crucial to select the right materials for the heat exchange between the LED chips and the aluminum bodies of the luminaires. In cooperation with Prague’s University of Chemistry and Technology, we found that thermally conductive materials – despite their name – often function as a heat barrier. Even high-quality thermally conductive paste (which ensures the heat exchange between the luminaire’s components) does not fulfill its purpose if it is not applied in very thin and very uniform layers. The difference of a mere tenth of a millimeter in the thickness of the adjoining layers is enough to significantly worsen the exchange of heat. This could result in quicker degradation and failure rate of LED chips.

In these situations, the idea that the more conductive paste we use, the better the exchange of heat will be is false. Every air bubble or poor fitting can also cause problems. Therefore, we use special thermally conductive tape with an ideal thickness and adhesiveness for the given material.

The thermogram of the Doublepower TaMAX SKY luminaire is proof that the attention we gave to the luminaire’s heat parameters paid off. Cooler luminaires are more economical and less prone to failure. That’s why they won’t hold up production, and will make up for their cost in even the roughest of conditions. The image below is from a test that one of our customers carried out in their demanding operating conditions.

Ideal proportions

In order to be sure of the perfect thermoregulation of our luminaires, we lowered the performance of our cooling surfaces . The dimensions of the other surfaces designated for cooling also take the collection of dust, grease, and other dirt into consideration.

The luminaires’ bodies were given generous dimensions and the proper thickness of material in the right places in order to insure that the exchange of heat from the chips to the cooling ribs takes place as fast as possible. Thanks to these measures, the thermal management of luminaires is extremely effective both directly after installation and throughout the whole course of operation.

Doublepower TaMAX SKY luminaires and Doublepower TaMAX TREE luminaires are available on the market and shine successfully in a number of extreme operations in the Czech Republic and abroad.